Polylatic Acid

PLA

Easy Setup

- Easy Storage

- No Special Conditions

- Minimal Warping

Things to keep in mind:

- Keep your printer away from windows and vents if possible

- Avoid humid climates

- Remove filament when not being used

Low Temperature

Recommended:

Nozzle: 210C

Bed: 60C

Other options:

- First Layer: 215C

- Other Layers: 210C

If there is no heated bed: Recommended:

Nozzle: 200C

Great for Most Applications

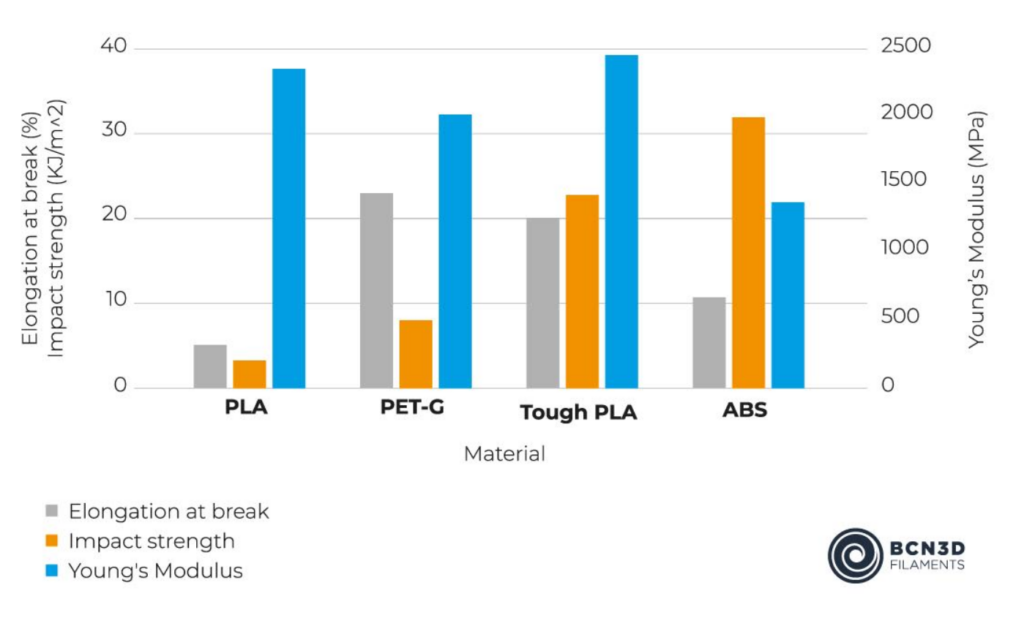

Tensile Strength: 50Mpa

Material Behavior:

- Brittle

- Hygroscopic (absorbs moisture)

- UV Degradation

Debugging Prints

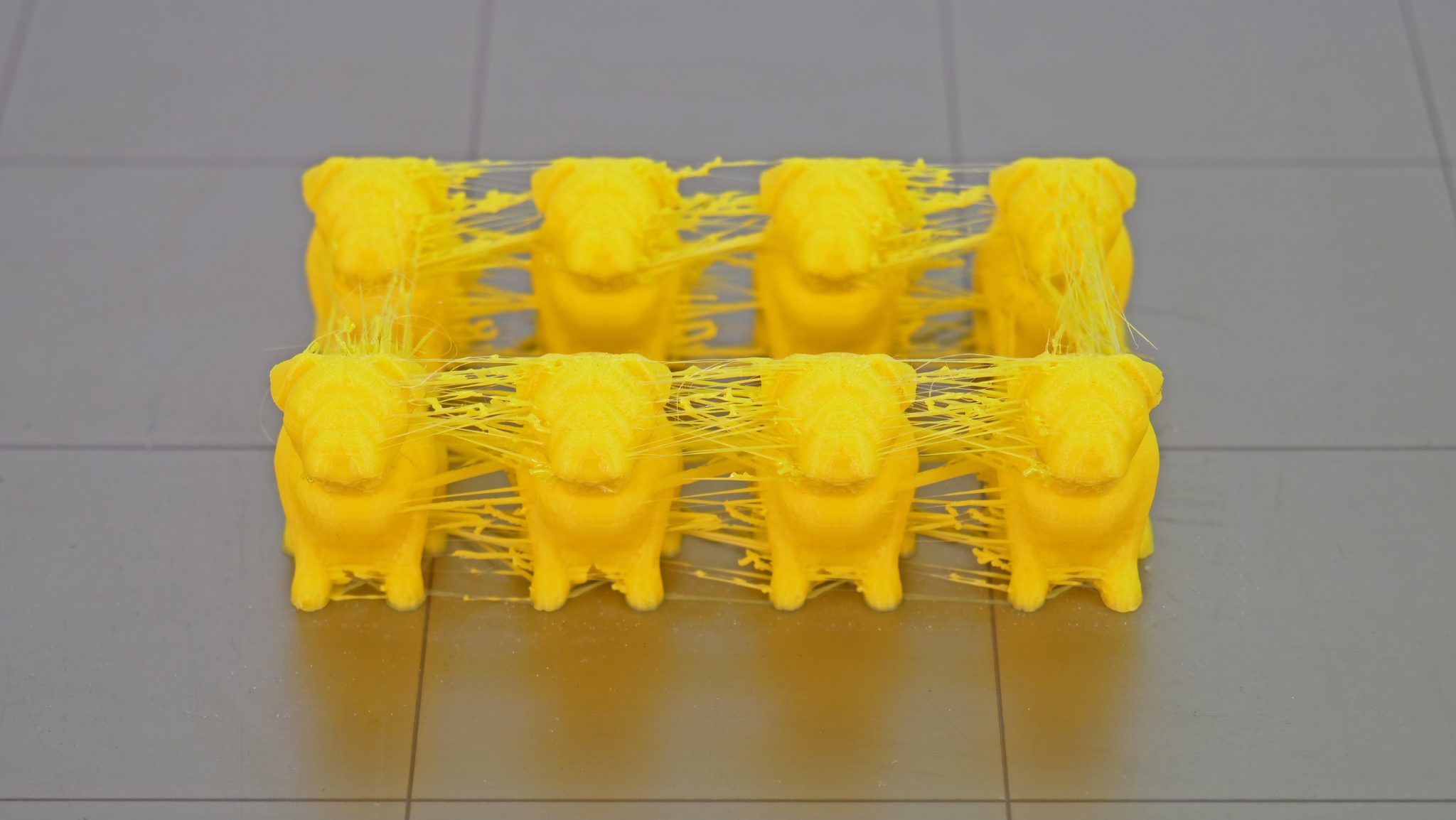

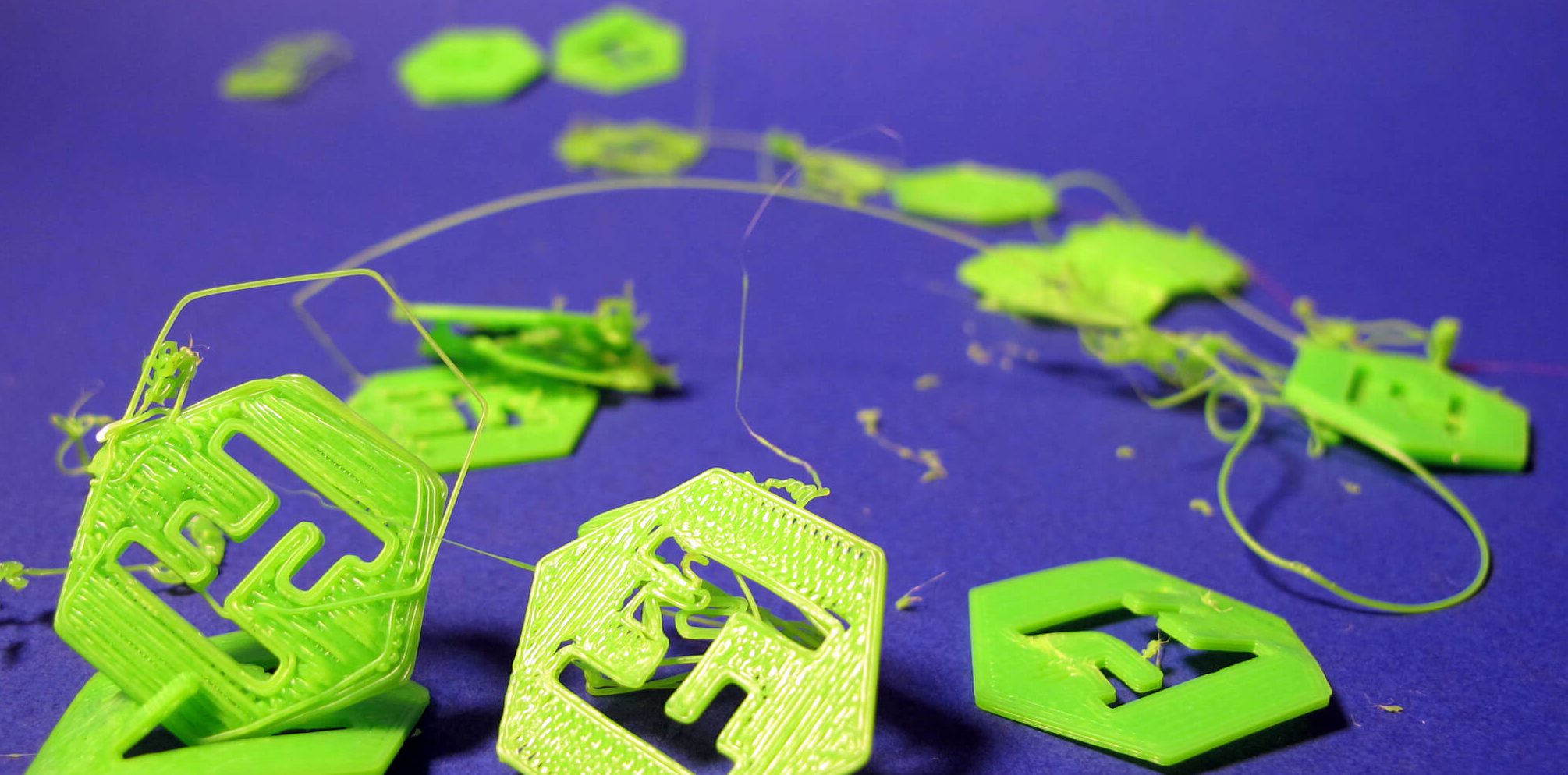

Stringing

Typically seen as a result of high traffic movements.

Main Causes:

- Retraction too low

- Temperature too high

Clean up:

Apply light heat

*too much heat will melt your part!

Cut off zits

Supports

Support overhang angles less than 45 degrees

How to fix: Reslice and add supports

Recommended settings:

Style: Organic

Overhang Threshold: 45

Top Contact: 0.2

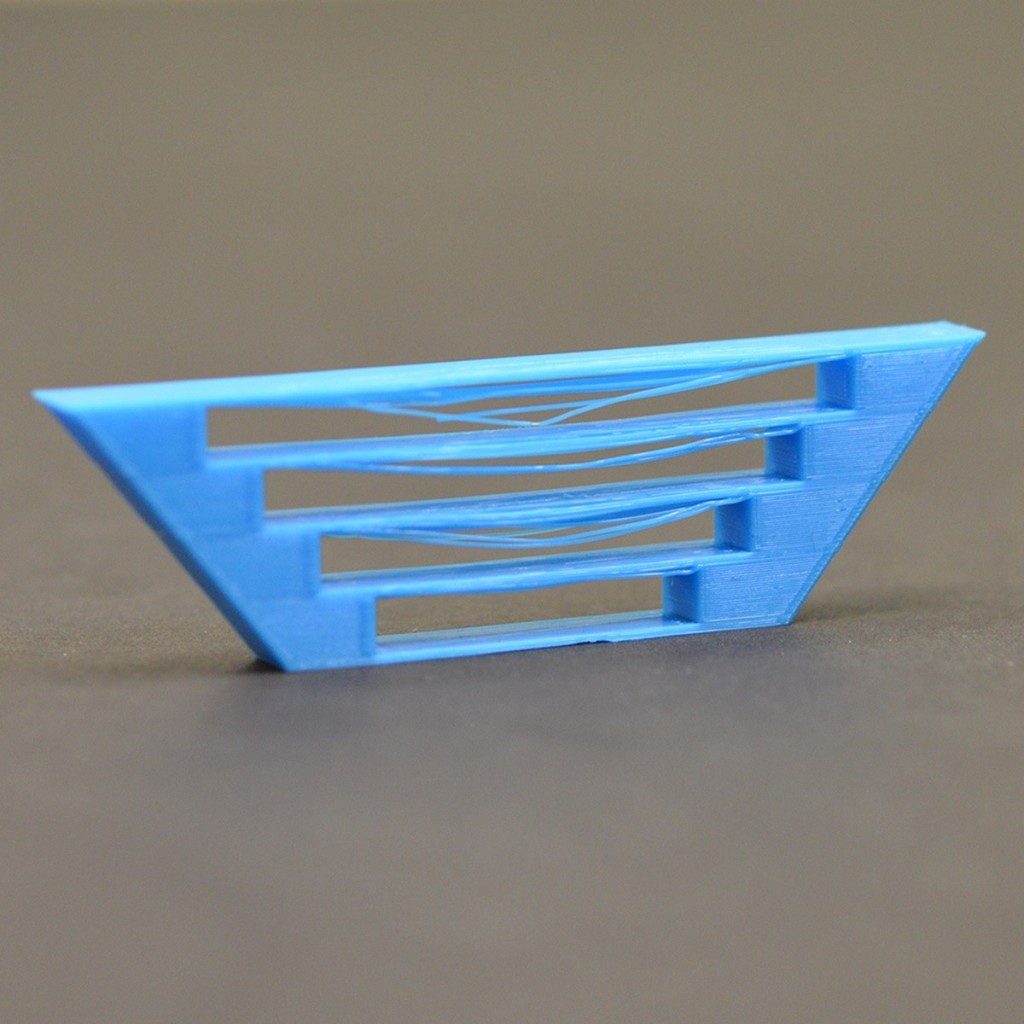

Bridging

Typically caused by temperature and print speed

*Time consuming-Takes some time to tune

How to fix:

Lower temperature

Lower print speed

*Requires a good ratio of the two

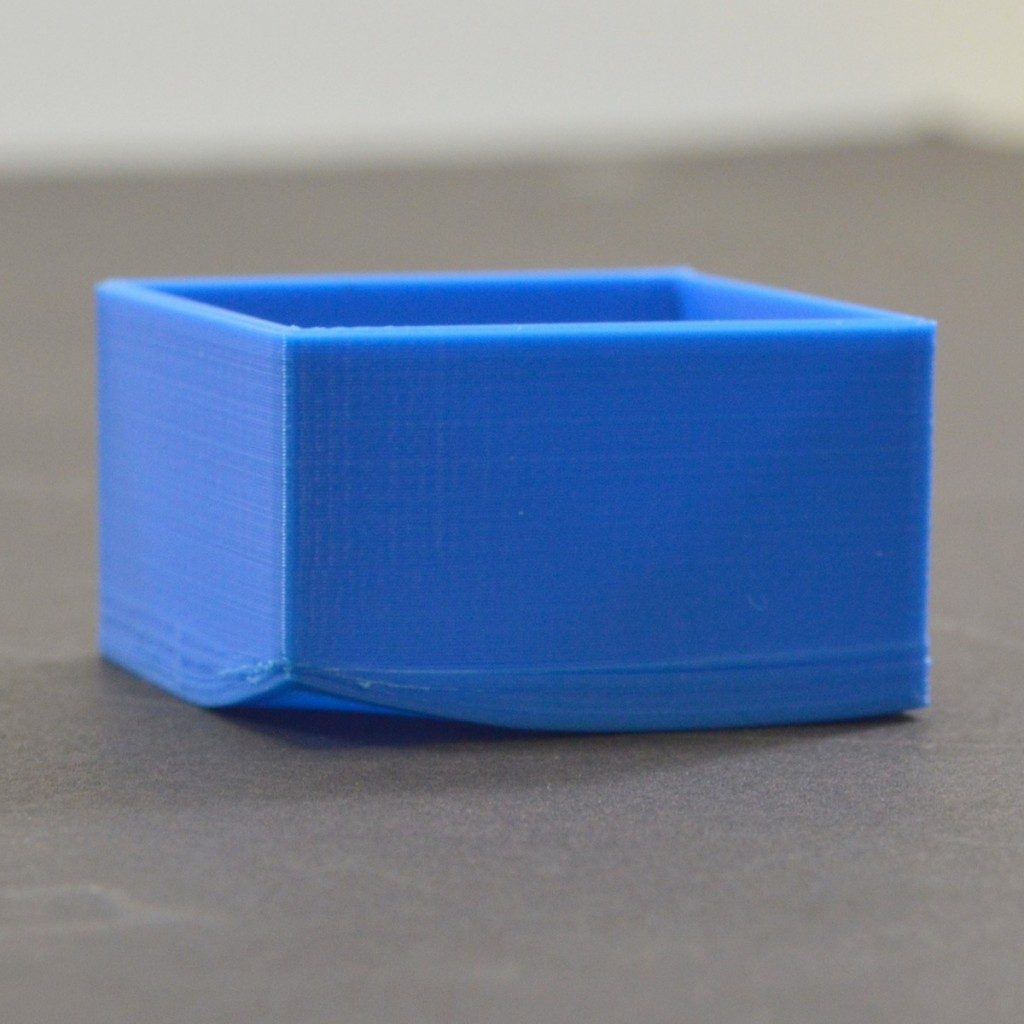

Warping

Typically caused by sharp corners and poor cooling.

How to fix:

Lower print speed

Lower temperature

Round sharp corners

Next step (if needed):

Clean nozzle

Dry filament

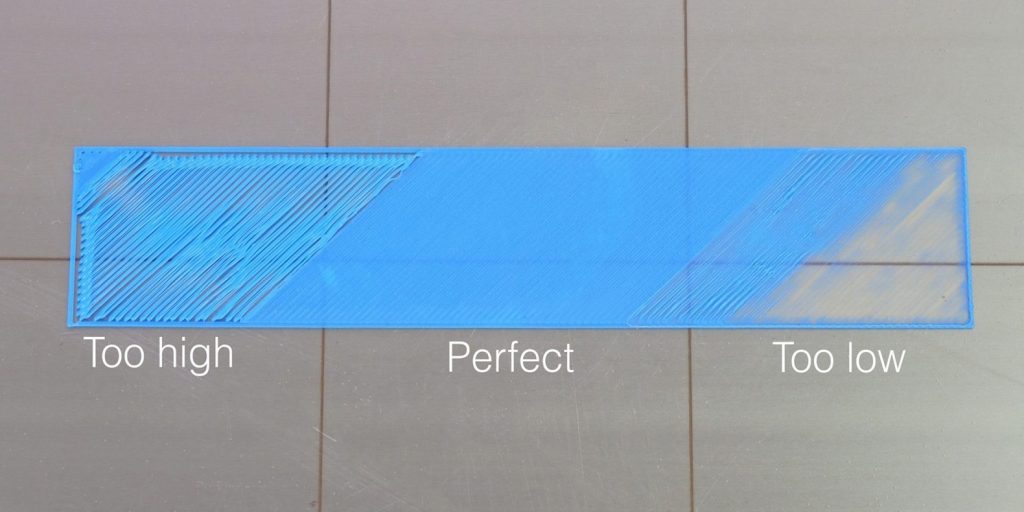

Bed Adhesion

Main Causes:

- Poor contact area with the build plate*

- Bed leveling

- Print speed too fast

- Layer height too high

- Not enough cooling

- Residue on build plate*

- Nozzle clog

- Moisture in filament

*Most Common

How to Fix:

Add a brim

Slow down the print speed

Turn on the cooling fan/Lower the temperature

Clean the build plate