Acrylonitrile Butadiene Styrene

ABS

Requires Enclosure

- Temperature Sensitive

- Prone to Warping

- Produces Fumes

Things to keep in mind:

- Vent your printer outside

- Avoid humid climates

- Avoid AC vents

- Remove filament when not being used

Temperature

Recommended:

Nozzle: 255C

Bed: 105C

*Requires Heated Bed

Not Recommended in Most Applications

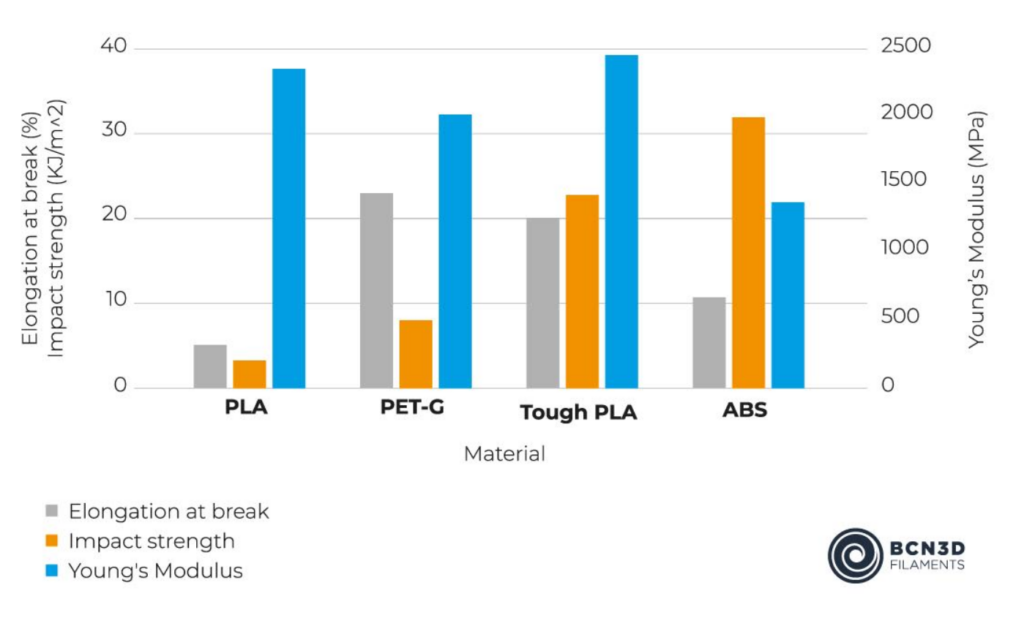

Tensile Strength: 43Mpa

Material Behavior:

- Temperature resistant

- Good impact strength

- Hygroscopic (absorbs moisture)

- UV degradation

- Shrinks when cooled

- Can be smoothed with Acetone

Debugging Prints

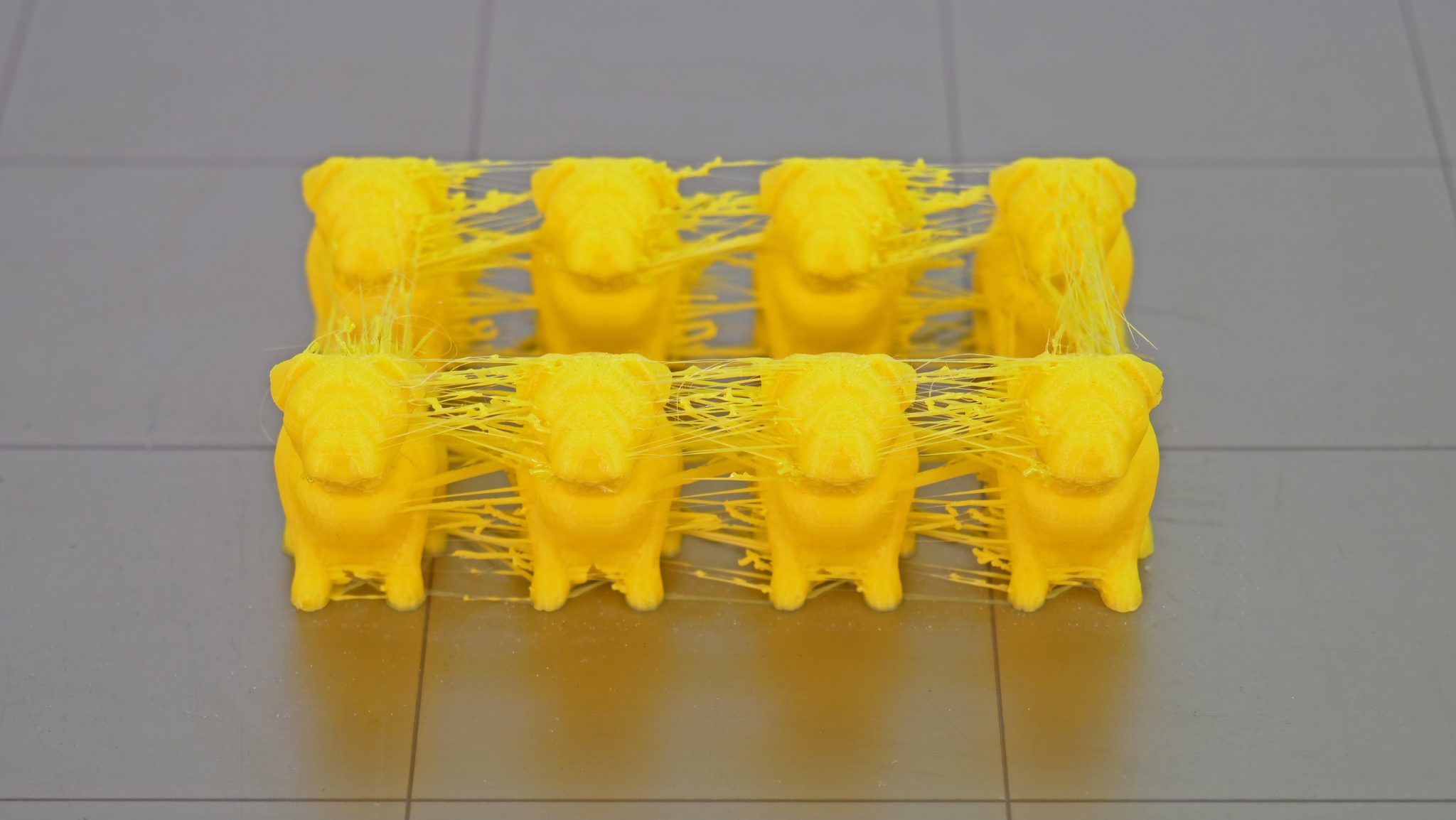

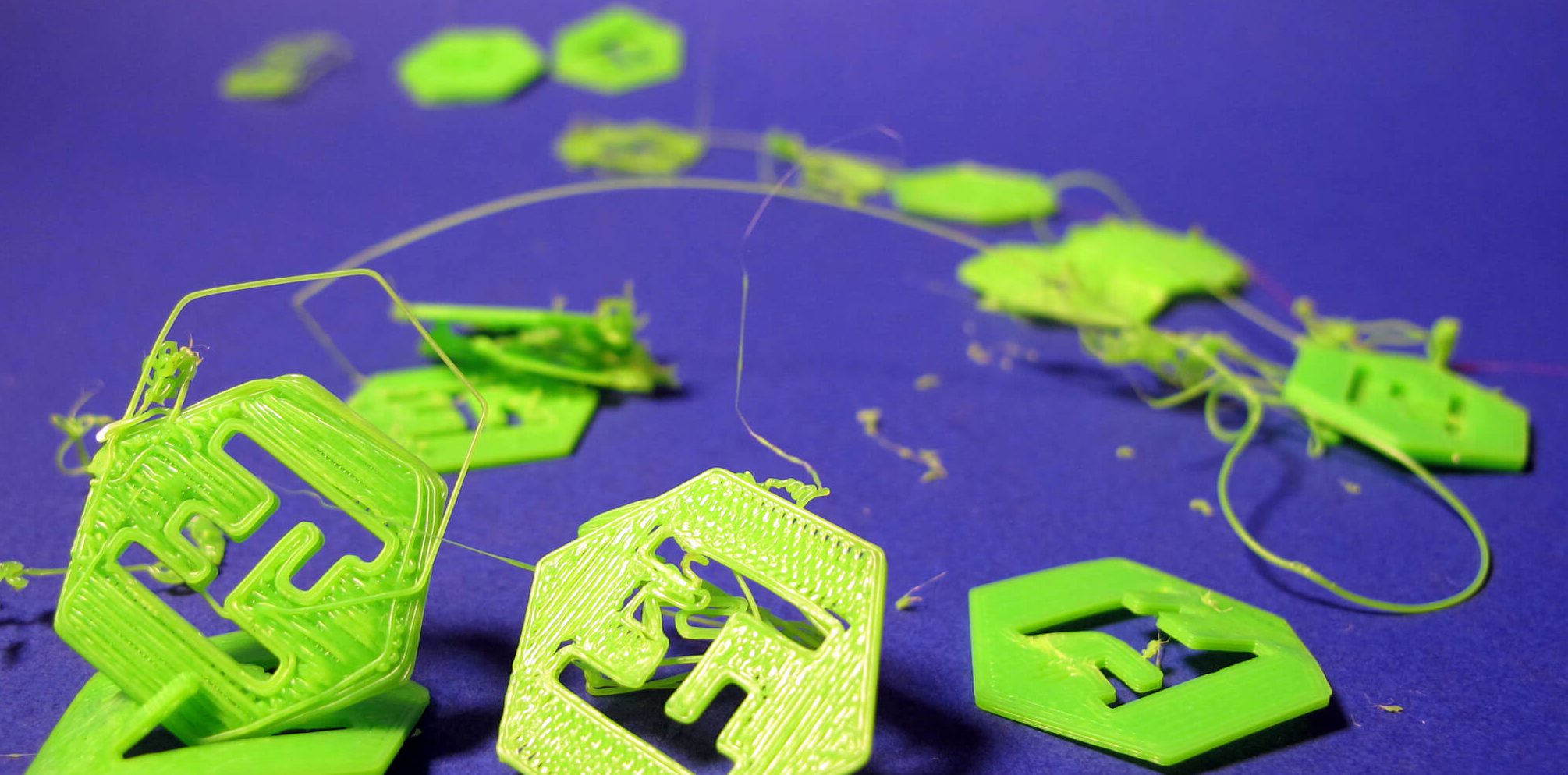

Stringing

Typically seen as a result of high traffic movements.

Main Causes:

- Retraction too low

- Temperature too high

Clean up:

Apply light heat

*too much heat will melt your part!

Cut off zits

Supports

Support overhang angles less than 45 degrees

How to fix: Reslice and add supports

Recommended settings:

Style: Organic

Overhang Threshold: 45

Top Contact: 0.2

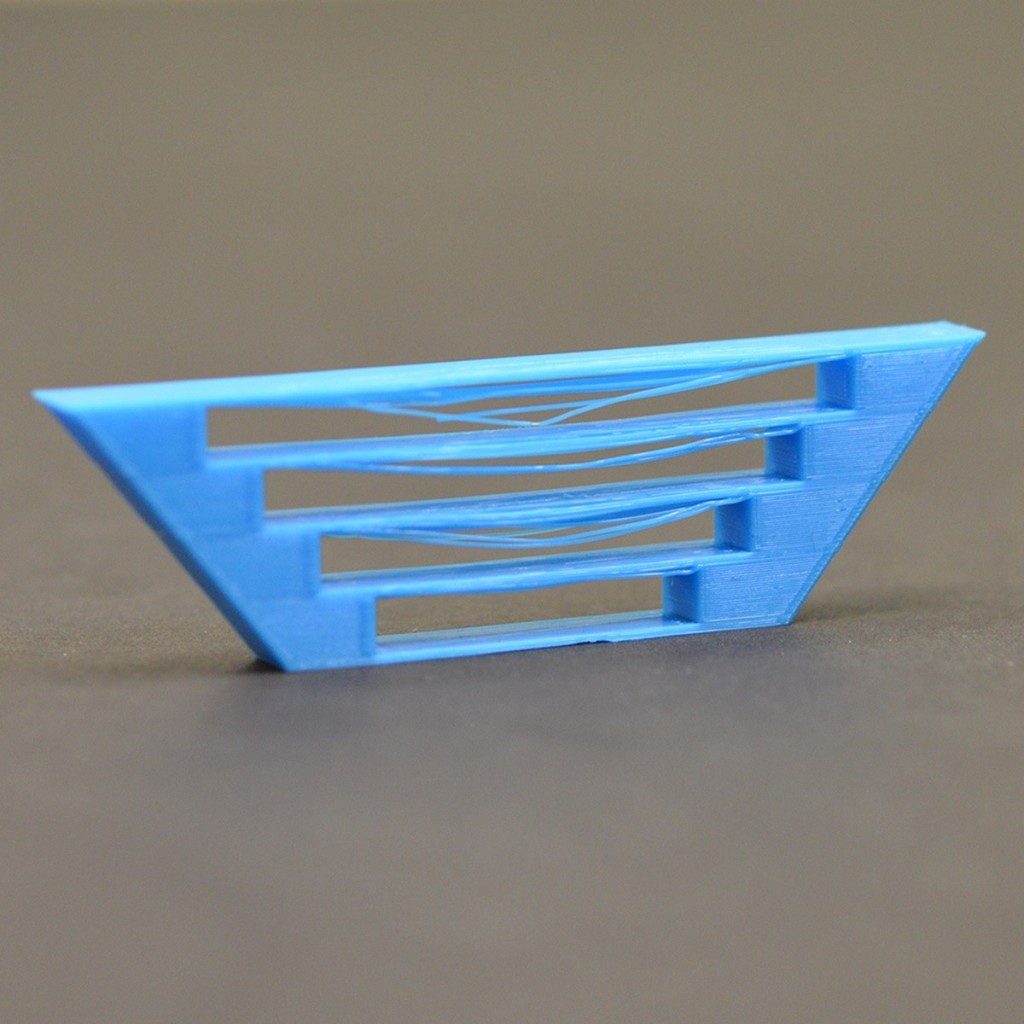

Bridging

Typically caused by temperature and print speed

*Time consuming-Takes some time to tune

How to fix:

Lower temperature

Lower print speed

*Requires a good ratio between the two

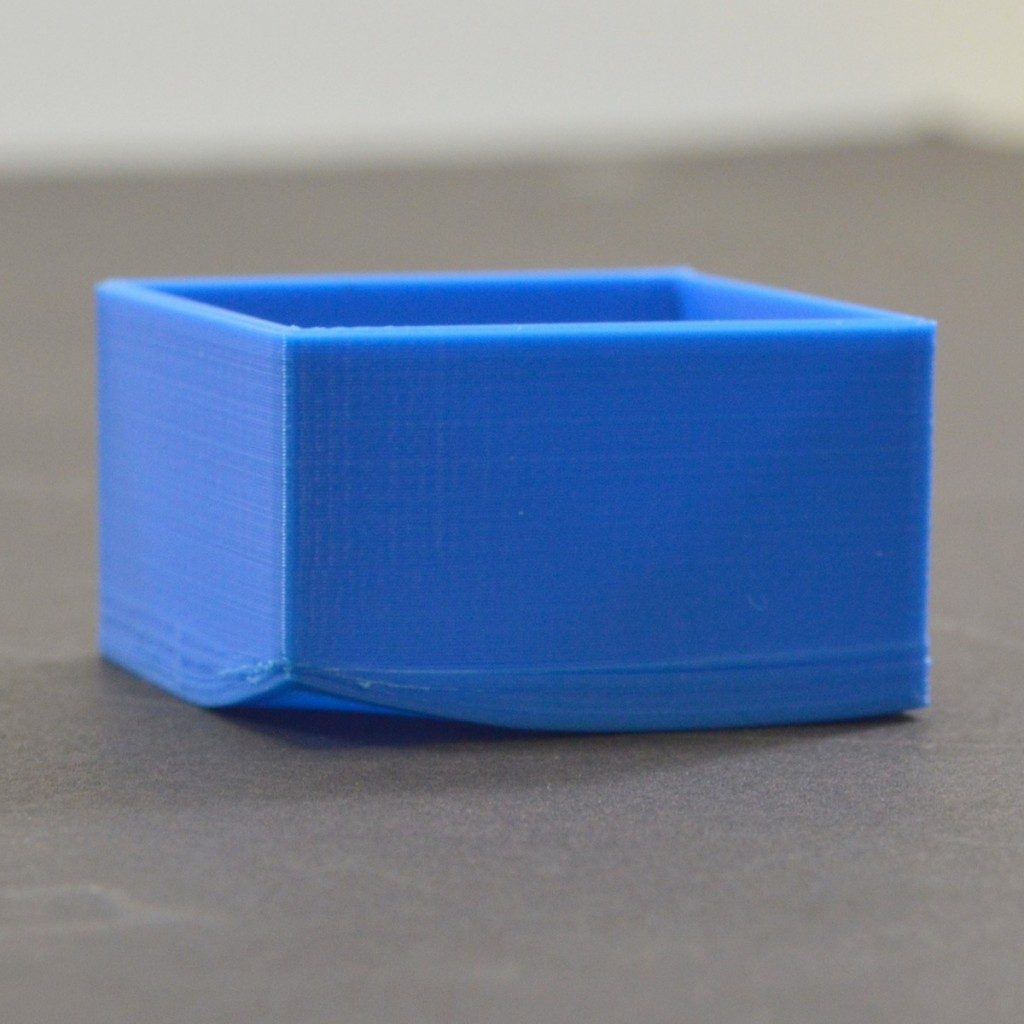

Warping

Typically caused by sharp corners and poor cooling

ABS is very sensitive to cooling. An ambient temperature of 40C is recommended.

How to fix:

Insulate enclosure

Lower print speed

Lower temperature

Round sharp corners

Next step (if needed):

Clean nozzle

Dry filament

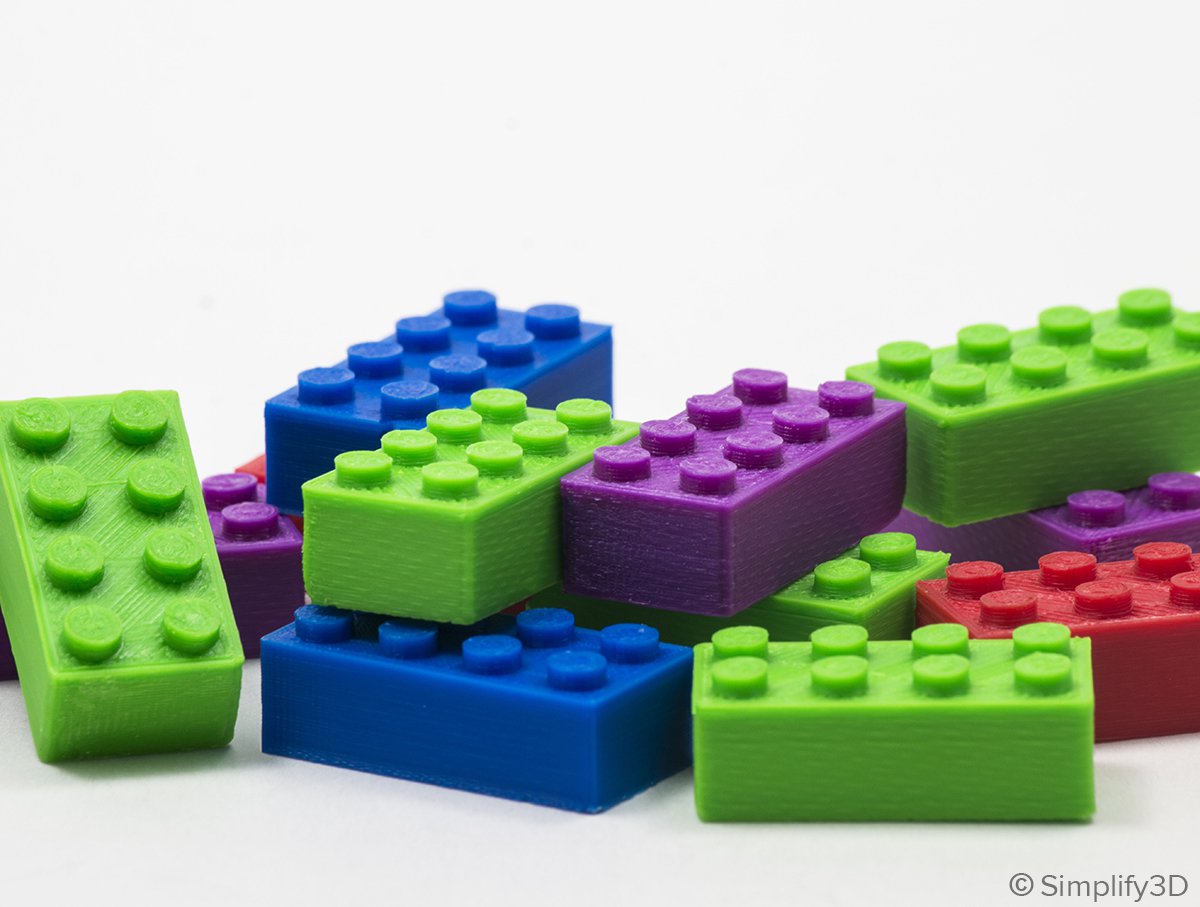

Bed Adhesion

ABS sticks easily and may require adhesives to mitigate damage to the build plate

What to use:

- Glue Stick

- Painters Tape

- Hairspray

Main Causes:

- Poor contact area with the build plate*

- Bed leveling

- Print speed too fast

- Layer height too high

- Not enough cooling

- Residue on build plate*

- Nozzle clog

- Moisture in filament

*Most Common

How to Fix:

Add a brim

Slow down the print speed

Turn on the cooling fan/Lower the temperature

Clean the build plate